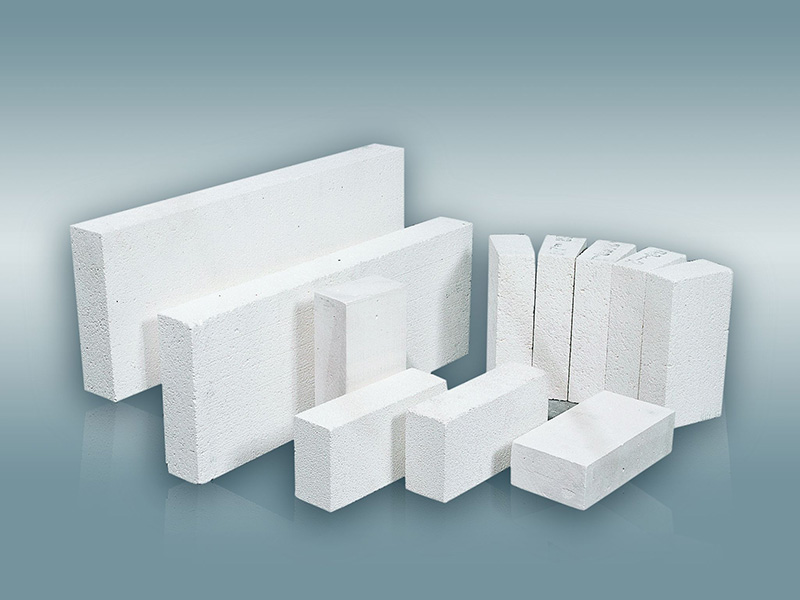

Isolated Fire Bricks

Isolated Fire Bricks

Isolated firebricks are insulation bricks which are light and resistant from 1200°C to 1730°C, having high thermal insulation. They are materials with uniform porosity distribution formed by the perfect mix of the raw materials of high-purity of refractory clay and ceramic. They don't contain undesired residues such as iron-oxide as they are manufactured from raw materials.

ADVANTAGES:

• They are manufactured with raw materials of high purity.

• Their size is fixed and no brick is any different than one another.

• They have low thermal shrinkage.

• They have a high compressive strength.

• They have low thermal conductivity.

• They can be used against direct heat sources. (foreground)

• They have high thermal shock resistance.

• There have a low heat capacity due to low densities.

• Easy to shape

• It is possible perform excellent insulations with low application costs on less thicker walls for their low density and high insulation effect

APPLICATION MORTAR:

It has been specially developed for applications of isolated bricks. They are available as ready-to-use with high purity and fine-sized raw materials. They are resistant to temperatures up to 1649°C. They are made of high purity ceramic raw materials and chemical binding.

|

ASTM C155-97 Classification |

20/23 |

23 |

25 |

26 |

28 |

30 |

32 |

|

ISO 2245 Classification |

125-0.5-L |

125-0.5-L |

135-0.8-L |

140-0.8-L |

150-0.9-L |

160-1.0-L |

170-1.25-L |

|

ClassificationTemperature ℃ |

1230 |

1230 |

1350 |

1430 |

1510 |

1620 |

1730 |

|

Density, ASTM C134-95 kg/m3 |

520 |

580 |

800 |

800 |

880 |

1030 |

1250 |

|

Cold Crushing Strength ASTM C133-97 Mpa |

1,2 |

1,8 |

2,5 |

2,2 |

2,5 |

2,5 |

3,5 |

|

Modulus Of Rupture (MOR) |

100 |

145 |

205 |

220 |

230 |

250 |

305 |

|

ASTM C133-97 |

0,7 |

1 |

1,4 |

1,5 |

1,6 |

1,7 |

2,1 |

|

Permanent Linear Change, % |

|||||||

|

ASTM C210-85 |

|

|

|

|

|

|

|

|

2250℉ 1230℃×24hrs |

0,0 |

0,0 |

|

|

|

|

|

|

2370℉ 1300℃×24hrs |

|

|

|

|

|

|

|

|

2460℉ 1350℃×24hrs |

|

|

-0,3 |

|

|

|

|

|

2550℉ 1400℃×24hrs |

|

|

|

-0,4 |

|

|

|

|

2732℉ 1500℃×8hrs |

|

|

|

|

|

|

|

|

2750℉ 1510℃×24hrs |

|

|

|

|

-0,9 |

|

|

|

2822℉ 1550℃×8hrs |

|

|

|

|

|

|

|

|

2912℉ 1600℃×8hrs |

|

|

|

|

|

|

|

|

2950℉ 1620℃×24hrs |

|

|

|

|

|

-1,3 |

|

|

3150℉ 1730℃×24hrs |

|

|

|

|

|

|

-0,9 |

|

Reversible Linear Thermal Expansion |

|||||||

|

(%) at 1100℃ |

0,45 |

0,48 |

0,48 |

0,48 |

0,49 |

0,5 |

0,55 |

|

Thermal Conductivity |

|||||||

|

ASTMC182-88 |

|||||||

|

Mean Temperature ℃(℉) W/m-k |

|||||||

|

200 (392) |

0.15 |

0.15 |

0.21 |

|

|

|

|

|

400 (752) |

0.17 |

0.18 |

0.24 |

0.27 |

0.26 |

0.39 |

0.49 |

|

600 (1112) |

0.19 |

0.20 |

0.28 |

0.30 |

0.29 |

0.42 |

0.50 |

|

800 (1472) |

0.22 |

0.23 |

0.32 |

0.33 |

0.31 |

0.43 |

0.51 |

|

1000 (1832) |

0.24 |

0.26 |

0.37 |

0.36 |

0.34 |

0.44 |

0.53 |

|

1200 (2198) |

|

|

0,4 |

0,38 |

0.37 |

0.48 |

0.56 |

|

Chemical Analysis |

|||||||

|

Alumina Al2O3 % |

50 |

50 |

50,5 |

56 |

67 |

73 |

77 |

|

Ferric Oxide Fe2O3 % |

0,9 |

0,9 |

0,85 |

0,8 |

0,6 |

0,5 |

0,4 |

|

Calcium Oxide CaO % |

0,29 |

0,29 |

0,29 |

0,29 |

0,24 |

0,22 |

0,2 |

|

Silica SiO2 % |

45 |

45 |

45 |

42 |

29 |

24 |

21 |

• In combustion chambers,

• In ceramic and porcelain furnaces

• In heat treatment furnaces using protective gas atmosphere

• In box-type heat treatment furnaces,

• As an insulation layer in pots

• On the side walls of glass furnaces,

• In general furnace applications.