Isolated Feeding Bricks

Isolated Feeding Bricks

They are bricks used in manufacturing the feeders that are used for the elimination of air gaps formed during the cooling of the metal in steel casting. Our bricks which don't react or stick to steel with no organic material have many advantages compared to the other feeding plates used in similar applications.

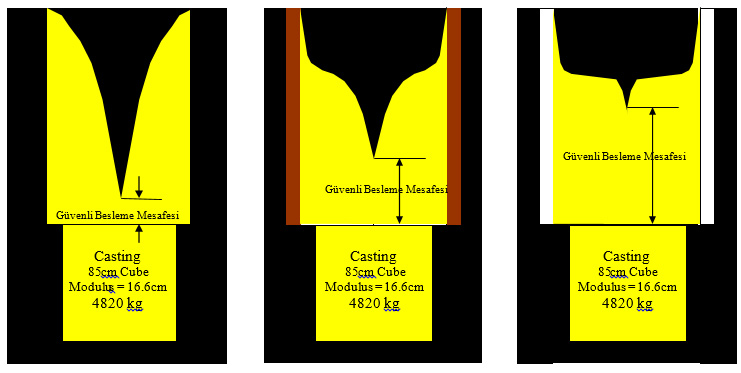

SAND - ISOTHERM - FEEDER PLATE COMPARISON

•Smaller feeder Isotherm use.

•Less Sand consumption.

•Smaller contact surface

•It saves time for the preliminary heat treatment required for steel.

•Smaller Size Feeder

•It doesn’t react with Steel

•Clean Feeder Surface Feeder

•Performing the same thing with Feeder Plate

•Isotherm feeder is 30% smaller.

Feeding Capacity for Sand, Fiber Plate and Isotherm Feeders

|

Sand Feeder |

|

Fiber Plate Feeder |

|

Isotherm Feeder |

Hardening after 800 minutes

|

Sand Feeder |

|

Fiber Plate Feeder |

|

Isotherm Feeder |

| Sand Feeder | Fiber Plate Feeder | Isotherm Feeder | |

|---|---|---|---|

| Module | 20.3 cm | 24.4 cm | 29.4 cm |

| Size | 100 cm ø 150 cm height | 100 cm ø 150 cm height | 100 cm ø 150 cm height |

| Time of Hardening | 800 minutes | 1170 minutes | 1730 minutes |

| Feeding Capacity | 13,000 kg | 25,000 kg | 50,000 kg |

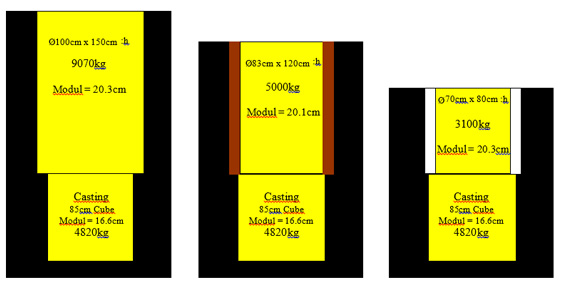

The Comparison of The Feeder Size For The Same Module

|

Sand Feeder |

|

Fiber Plate Feeder |

|

Isotherm Feeder |

Comparative Feeder Size In Compliance With The Material It Feeds

.jpg)

|

Sand Feeder |

|

Fiber Plate Feeder |

|

Isotherm Feeder |

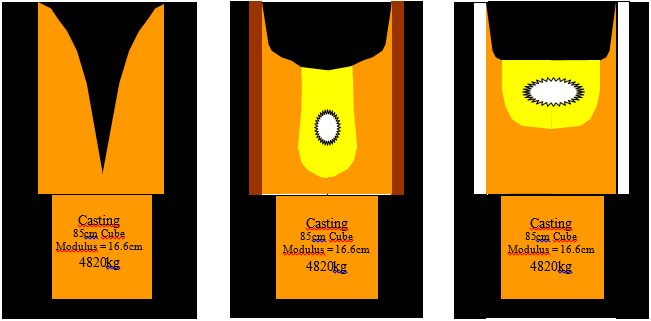

Fiber Plate Feeders

• After burning, the resin has an affect similar to sand feeder.

• The effect of burning is visible on the neck area.

• Due to the combustion of the plate, bulk forming is seen on the metal during the embankment.

• The Feeding Module ranges between 1.15 and 1.3 according to its size.

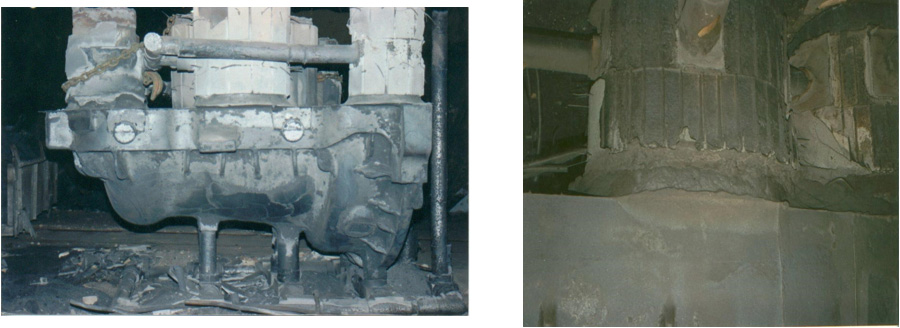

Actual Comparison

• As a result of pouring the same particle with Isotherm Feeder

• For the same particle size

• Smaller feeder size.

• No reaction with steel.

• Clean and smaller feeder neck

The differences between Isotherm Feeder bricks and Fiber Feeder Plates

|

ISOTHERM |

THE FEEDER PLATE |

|

Ceramic connected |

Chemical connected |

|

No organic material |

Consists of high amount of organics |

|

No reaction with liquid steel |

Reaction with liquid steel |

|

Doesn’t stick to steel |

Penetration on the surface of steel |

|

Low density (0,6 g/cm3) |

Density 0,8 -1,0 g/cm3 |

|

Expanding Module Factor 1,52 |

Expanding Module Factor 1,30 |