RESISTANCE WIRES

KANTHAL (FeCrAl) and NIKROTHAL (NiCr) heating elements are used as heating elements in industrial furnaces and electrical household appliances. Products that may be preferred depending on the application are as follows;

KANTHAL A1: It's a heating element with maximum use temperature of 1400˚C, consisting of iron-chromium-aluminum alloy, with a stable oxide layer.

KANTHAL AF: It's a heating element with maximum use temperature of 1300˚C, consisting of iron-chrome-aluminum alloy, with a stable oxide layer.

NIKROTHAL: It's a heating element with advantages of a higher creep resistance compared to aluminum-based resistances, ductility protection after use, being non-magnetic, and a higher corrosion resistance. Is a heating element having advantages such as higher corrosion resistance. The maximum operating temperatures that change depending on the nickel ratio are as follows;

Nikrothal80 - 1200C

Nikrothal70 - 1250C

Nikrothal60 - 1150C

Nikrothal40 - 1100C

KANTHAL APM: It's a heating element that has been developed for high temperature applications where conventional electrical heating alloy causes problems, being manufactured by high "Powder Metallurgy" technique. The maximum operating temperature of the elements consisting of iron-chrome-aluminum alloy is 1425˚C.

It has advantages of minimum deformation at high application temperatures, minimum use of suspension and connectors, minimum change in resistance during use, longer equipment life, high protection in corrosive environments, minimal disruption of the protective oxide layer and minimum emprüt formation.

KANTHAL D: It's a heating element with maximum use temperature of 1300˚C, consisting of iron-chromium-aluminum alloy. Compared to the products; Kanthal A1 and Kanthal AF, it is recommended to be used in lower furnace temperatures due to a lower resistance value.

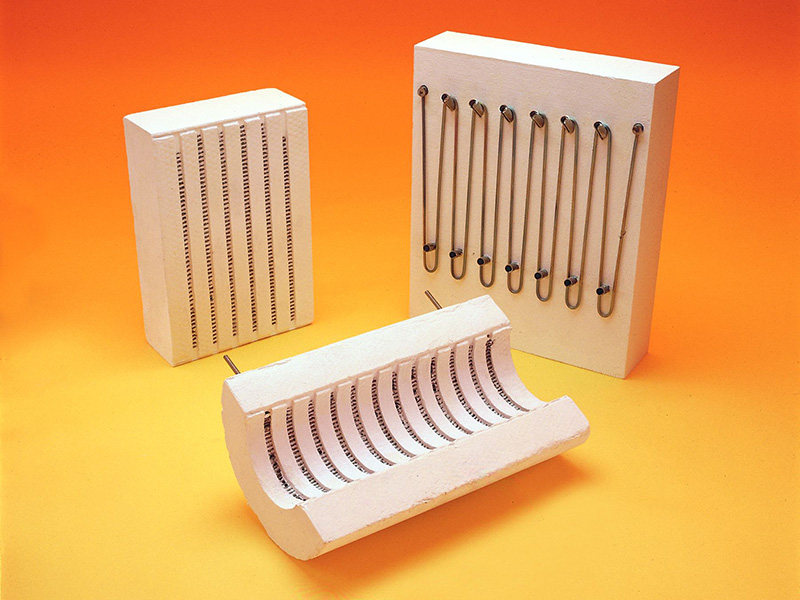

HEATING SYSTEMS

TUBOTHAL HEATING ELEMENTS: Tubothal electric heating systems have been developed as a combination of the design of heating elements improved with APM wire and idea of "maximum power, maximum life". Tubothal heatings can reach up to 40KW power and used horizontally or vertically without any support system for their light design compared to traditional heatings with a ceramic body. Due to the APM wire used in the production of Tubothal heatings, their performance is higher than other heatings.

KANTHAL APM TUBES: In applications with a limited volume of furnace, APM tubes with a smaller diameter can be used a heating element and thanks to the large tube surface, it can be reached up to higher power.

EXTRUDED KANTHAL APMT TUBES: They are tubes manufactured with the extruding technique from iron-chromium- aluminum alloys for gas and electric heated industrial furnace applications.

FIBROTHAL: They are complete modular construction systems for heating and insulation purposes.

GLOBAR: It's a heating element based on silicon carbide with maximum operating temperatures that can reach up to 1625˚C.

KANTHAL SUPER: It's a heating element based on molybdenum disilicide with a maximum operating temperature that can reach up to 1850˚C.

OTHER SYSTEMS: Ceramic-based electrical heating products (Moduthal), special ceramic and fiber materials (Maxthal), thermocouple wires